system monitoring micro flowmeter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is main flowmetering equipment R&D and production company. The company"s flowmeter andgear pump in scientific research, development, production status.After severaldecades of reform and development, JSN has formed a company model ofindependent development, production, testing, sales and service integration.70% of its products are exported to foreign countries, and have undertakenmajor projects in China, and key enterprises in the industry. Pump supportingprojects. It has been promoted and applied in various engines, polyurethane,dispensing, chemical, lubrication, chemical fiber and other industries inChina.Main products: micro flow meter,oval gearflow meter ,coriolis mass flow meter,electromagnetic flow meter,piston flowmeter,spur gear flow meter,gear pump,gear metering pump etc.

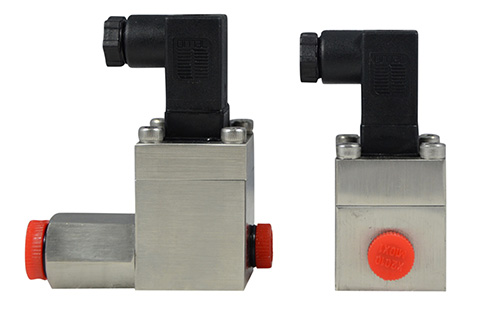

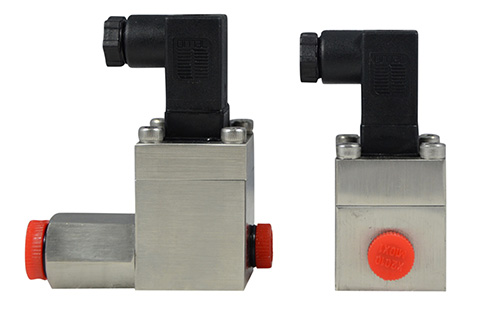

system monitoring micro flowmeter

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Whymany customers gradually from the major international brands MAX, OVAL Obar,KRACHT Clarke and other gradually purchased base deep Oval gear flow meter it?Many customers also have questions: why base depth can be reported Oval gearflow meter so good? This stems from our engineers is a former Siemens seniorengineer, the device is also fully adopted Siemens CNC machining center, thecutting height of 0.001mm, to ensure that our flowmeters minimum flow meter canbe measured to 0.1ml / min, which are at home and abroad are Rare, the currentproducts have been awarded the national measurement certificate, and ISO, SGS,CE, after thousands of customers hundreds of conditions medium test, once againwe are very grateful to the recognition of domestic and foreign customers.Attitude, carrying domestic and foreign customers look forward to working hardto make real benchmarking business.

system monitoring micro flowmeter

The Ovalgear flow meter is a volumetric flow meter that consists of a flow chamber in achamber and one or several elements that are rotated by fluid flow to form aflow meter. Leakage between the rotating element and the inner wall and theselected working range The internal flow rate is negligible. The rotation ofthe element is transmitted mechanically or by other means to the indicatingdevice to indicate the volume flow of the fluid flowing through.

system monitoring micro flowmeter

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

What are the precautions for the gear flow meter?

1) In the field installation, it should be noted that the direction of the arrow on the flow meter housing is consistent with the flow direction of the fluid;

2) The flowmeter is installed on the same pipe with the same nominal internal diameter as the inlet and outlet fittings. When the pipe is connected with the flowmeter, the seal should not protrude into the fluid;

3) The fluid to be measured shall be filled with the metering room of the flowmeter and the connecting pipes before and after it. If the fluid to be measured contains gas, a gas separator shall be installed before the flowmeter and the filter;